Setting the Fluid Power Industry in Motion

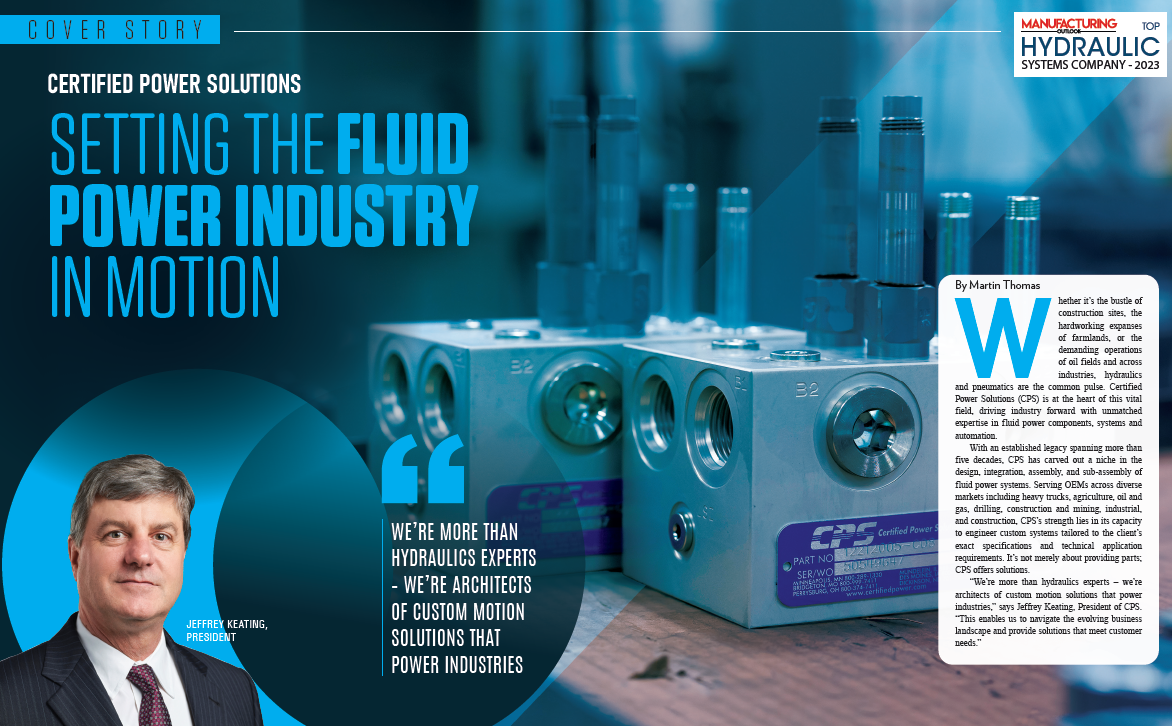

Certified Power Solutions

Whether it’s the bustle of construction sites, the hardworking expanses of farmlands, or the demanding operations of oil fields and across industries, hydraulics and pneumatics are the common pulse. Certified Power Solutions (CPS) is at the heart of this vital field, driving industry forward with unmatched expertise in fluid power components, systems and automation.

With an established legacy spanning more than five decades, CPS has carved out a niche in the design, integration, assembly, and sub-assembly of fluid power systems. Serving OEMs across diverse markets including heavy trucks, agriculture, oil and gas, drilling, construction and mining, and industrial, and construction, CPS’s strength lies in its capacity to engineer custom systems tailored to the client’s exact specifications and technical application requirements. It’s not merely about providing parts; CPS offers solutions.

“We’re more than hydraulics experts – we’re architects of custom motion solutions that power industries,” says Jeffrey Keating, President of CPS. “This enables us to navigate the evolving business landscape and provide solutions that meet customer needs.”

Engineering Solutions, One Customer at a Time

Engineering Solutions, One Customer at a Time

To stay at the forefront of the industry, CPS has doubled its investment in research and development over the past two years. This strategic move is aimed at creating the products, solutions, and proprietary systems that will shape the industry’s future.

Furthermore, recent acquisitions, including Skarda Equipment, reflect more than just growth for CPS. They’re about injecting fresh ideas, adding skilled personnel to the team, and broadening the company’s focus on delivering premier fluid power products to its customers.

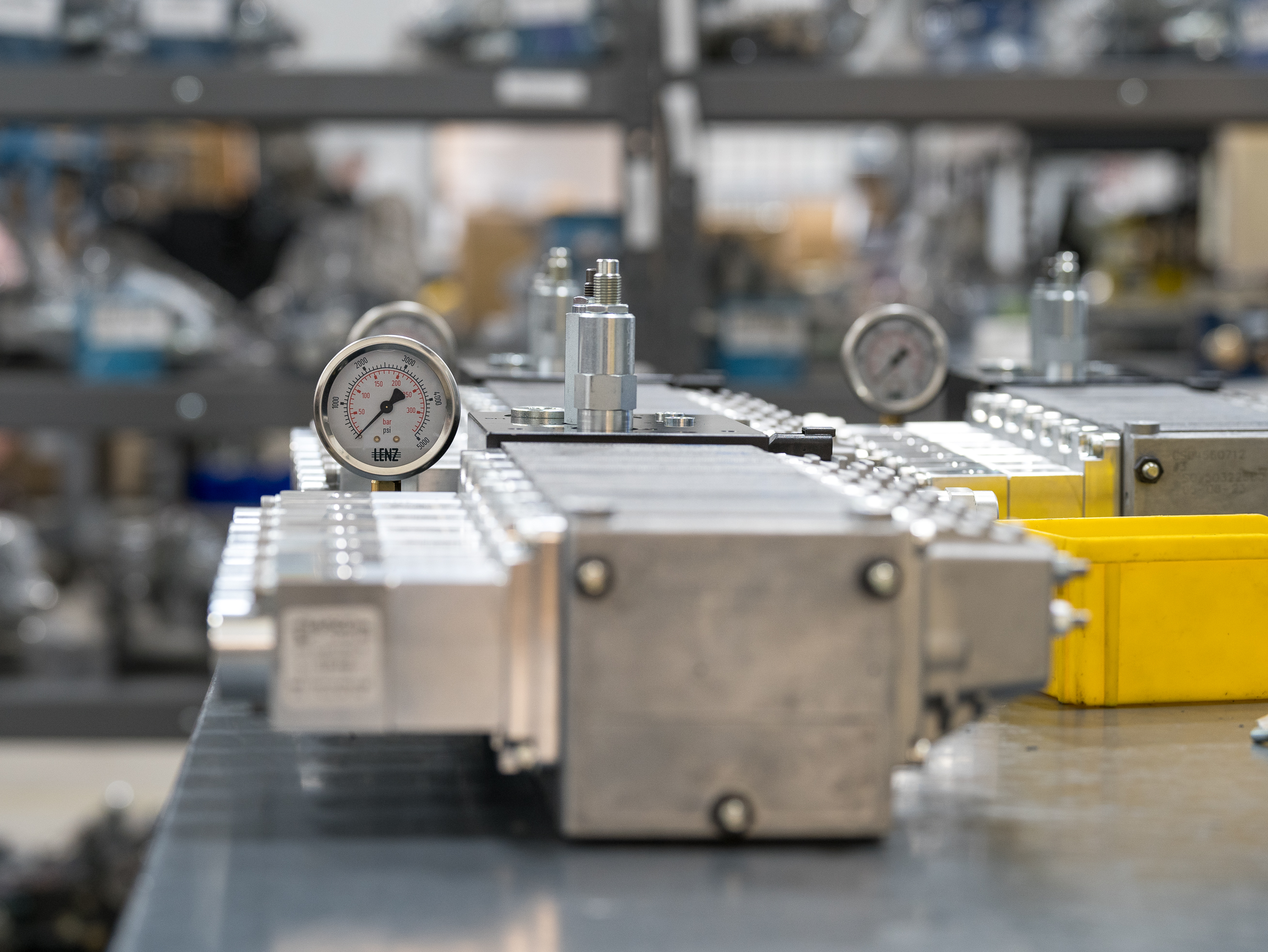

Integral to the company’s investment in R&D, CPS’s engineering teams have been an important pillar to its success. They take on full design responsibility for every project, from a project’s inception to its final design, and bring expertise that spans a wide range of areas, including automation, systems, controls, and human-machine interfaces (HMI).

Just as essential is CPS’s knowledgeable sales force, serving as an invaluable connection point in understanding customer needs and translating these insights to the engineers. Through effective collaboration with technical teams, customers receive solutions purpose-built to their needs, underscoring CPS’s commitment to a customer-centric approach.

Beyond Hydraulics

As a market leader in the snow and ice industry, CPS goes beyond traditional hydraulics expertise by delivering packaged solutions that integrate hydraulics, controls, HMI, and custom software. Additionally, CPS has leveraged its technology to introduce its new cloud-based telematics solution, FleetPilot Connect. This, along with the broader FleetPilot ecosystem, enables seamless, tech-agnostic connectivity between transportation departments, municipalities, and their drivers.

As Keating emphasizes, these advancements are not just about technology, they’re about “improving productivity, saving lives, and protecting property.”

Moreover, CPS expanded their snow and ice reach this year with the introduction of SnowPak, a system designed for commercial businesses and municipalities, further illustrating the company’s commitment to solving customer challenges.

Keating added, “The transformation that these systems bring to the communities they serve is profound. A clear road is more than a path; it’s a bus route to your child’s school, your safe passage to the grocery store or to work every day, a truck’s highway to bring goods to market.”

|

|

|

Design Responsibility and Turnkey Solutions

For CPS, design responsibility isn’t just a concept—it’s a way of serving customers better. This means building turnkey solutions and providing ongoing support throughout the duration of the equipment’s lifecycle.

Building on this, CPS solutions balance cost efficiency and superior machine performance. Integrating leading technologies from reputable, best-in-class vendors has proven a reliable formula to guarantee final designs that surpass OEMs’ expectations.

Keating states, “Our value proposition extends beyond products—we offer holistic services including system design, engineering, installation, testing, and maintenance, providing an integrated and seamless experience for our clients.”

In its OEM distribution business, CPS takes a unique approach. Instead of being limited by standalone technologies or product lines, the team can architect solutions across a broad spectrum of product technologies. Additionally, the company considers electrical alternatives, especially in instances where the application of pneumatic or hydraulic force profiles aren’t required, or when the operating environment call for alternative motion solutions.

Embracing Electrification

CPS is driving innovation through its focus on electrification. As new environmental standards emerge, the company has embraced electrical and hybrid alternatives to traditional hydraulic systems, including controls and linear actuators. With extensive expertise in custom software solutions, CPS designs systems to control electrohydraulic actuators that provide valuable operator feedback on a machine’s safety and operational health.

The company’s strength lies in its proficiency in electric, pneumatic, and hydraulic motion control, PLC programming, and panel building. This expertise enables the company to deliver diverse, cost-effective automation solutions—from basic component assemblies to intricate multi-motion control systems.

This shift towards electromechanical solutions is particularly critical in industries like food and beverage, where minimizing hydraulics in manufacturing and processing areas is a priority. By continuously innovating, CPS promotes cleaner and more efficient operations for customers, demonstrating its commitment to meeting their unique industry requirements.

CPS’s flexibility is a differentiator that enables the company to cater to such a diverse set of customer needs.

Navigating Supply Chain Challenges

Post-COVID, CPS continues to navigate supply chain challenges, ensuring customers have the products they need when they need them. Through creative strategies like single-customer consigned inventory and custom stocking programs, CPS is doing their part to mitigate supply chain issues for its customers.

Furthermore, recognizing the challenges that labor shortages pose, CPS offers pre-assembled, total system solutions. These fast and efficient turnkey offerings enable customers to strategically allocate their resources, while entrusting CPS with tasks such as building hydraulic systems and related components. By doing so, customers can free their workforce to focus on core competencies.

As Keating sums it up, “We put the customer at the center of everything we do. Their visions drive our innovation and designs. If they can dream it, our teams will find a way to build it.”

Accelerating Advancements in Fluid Power

Customers seeking to diversify their supply base to mitigate risk will find an extensive array of options with CPS. Serving as an all-inclusive distributor, CPS offers a diverse portfolio of suppliers, technologies, and services, ensuring customers find the optimal solution to meet their specific needs.

Amidst the industry’s rapid change, CPS aims to cement its status as a leader, setting a powerful example for the future of the fluid power industry.

Interested in seeing the September Manufacturing Outlook article, visit: themanufacturingoutlook.com

Recent Posts

- Visit Our Booth at Work Truck Week 2024

- CPS: Setting the Fluid Power Industry in Motion

- Skarda Press Release